LRC radio controlled overfill prevention product overview

LRC SMALL REMOTE

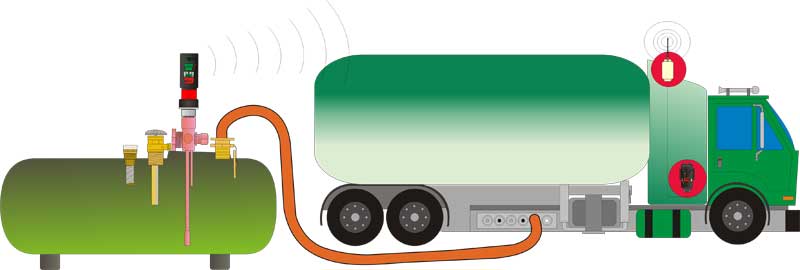

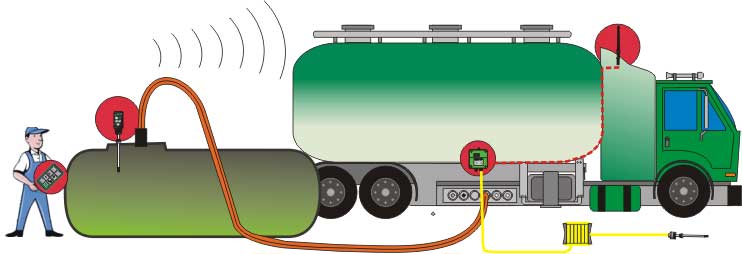

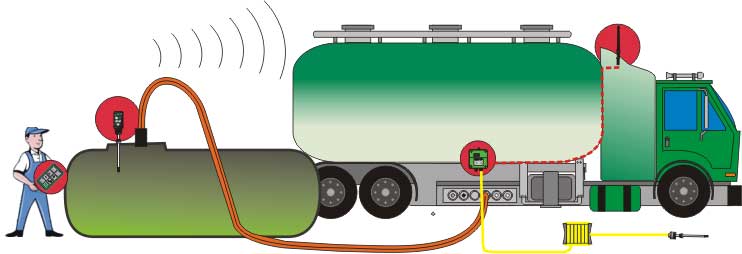

LRC-Small is a complete radio controlled overfill prevention system. It is designed for the filling of stationary and mobile tanks (e.g. tank trucks).

The following functions can be carried out with LRC Small:

- Motor (pump) start / stop

- Filling start / stop

- Rotational speed control

- Filling process interruption

- Wind / rewind hose drum

- Dead man's function

- ANA function (Germany)

- Automatic fill stop

The following types of limiters can be addressed:

- Limit value transmitter according to TRbF (PTC thermistor probes - German standard EN13616)

- Float probes (nose on 10h)

- Optical limit switches (Swiss standard, ship standard BeNeLux)

- Probes with relay contact

Overfilling is reliably prevented in combination with limit probes. The devices are approved for use in both potentially explosive and non-hazardous areas.

Applications LRC Small:

- Discharge of all liquid products and powdery / granular substances from the tanker / container to the tank

- Loading of tanker / container at the depot and terminal wagon refueling / wagon unloading

- Ship, boat, aircraft and helicopter refueling

- Industrial applications for radio remote control of all kinds in hazardous areas.

ADVANTAGES LRC SMALL RADIO CONTROLLED OVERFILL PREVENTION:

- Overfill prevention without compromise

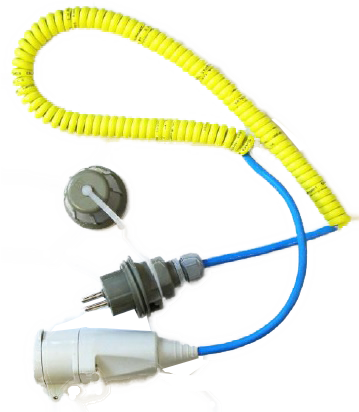

- No use of cables

- Optimized loading/unloading processes

- Simplified work processes

- Time and cost savings

- Safety and productivity increase

- Environmental protection

- Suitable for any product

- "Fail Safe" and "Fail to Safe System"

Application field/ Pictures of LRC

Overspill and Overfill Prevention Systems

Overspill and Overfill Prevention Systems  LRC Level Remote Control - Radio controlled overfill prevention

LRC Level Remote Control - Radio controlled overfill prevention  LRC REC2

LRC REC2  Produkte

Produkte  Ab- und Überfüllsicherungssysteme

Ab- und Überfüllsicherungssysteme Overspill and Overfill Prevention Systems

Overspill and Overfill Prevention Systems  LRC Level Remote Control - Radio controlled overfill prevention

LRC Level Remote Control - Radio controlled overfill prevention  LRC REC2

LRC REC2  Produkte

Produkte  Ab- und Überfüllsicherungssysteme

Ab- und Überfüllsicherungssysteme