LRC ADN SHIP LOADING

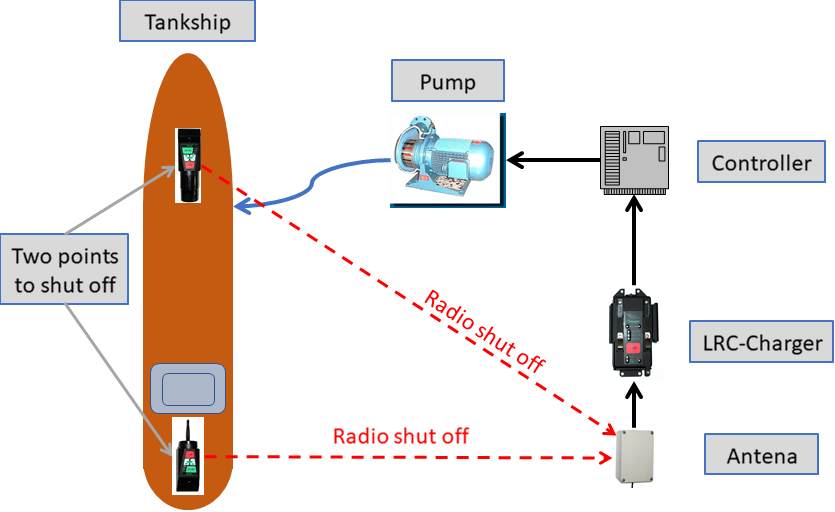

When loading the tanker-ship, the system automatically monitors the limit of the ship's tank as well as the complete load by connecting it to the usual nose probe 10h. During filling, it is possible to interruped or stop the filling from 2 independent positions using our EX-Remote system (dead man / emergency stop). On the shore, the system is permanently connected to the port's process control system and controls the complete filling via radio. Overfill is not possible. This system works without a cable connection between land and ship and thus significantly increases the occupational safety of the user. To guarantee long loading times (up to 36 hours of continuous operation), the LRC ADN battery case is used.

When loading or unloading of hazardous fluids from

- Class 2 (gases) or

- Class 3 (Flammable Liquids),

- UN 1280 (propylene oxide) or

- UN 2983 (ethylene oxide and propylene oxide, mixture with at most 30% ethylene oxide),

must be monitored on

- two places on the ship (front and back) and on

- • two places on land (directly at the entrance to the ship and at a sufficient distance)

must be interrupted by a loading / unloading switch, this means the quick-acting valve close directly the movable connecting line between ships and land. Each tanker shall be equipped with a limit switch for the overfill prevention which triggers at the latest state of filling of 97,5%;

The limit switch (according to 9.3.2.21.1 d) on board have to trigger

- an optical and

- acoustic alarm and

- simultaneously to actuate an electrical contact that can interrupt in the form of a binary signal passed from the land system and fed current loop and can initiate land-side measures against overfill during loading.

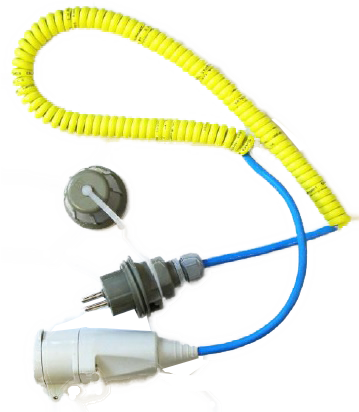

The signal must be sent to the land plant by means of a

- Double pole cable,

- waterproof plug of a coupling plug device according to the standard EN 60309-2: 1999 for,

- Direct current from 40 to 50 V

- Color code white,

- Position of the auxiliary nose 10h, can be passed.

- The plug must be firmly attached to the ship in the immediate vicinity of the shore connections of the charging and discharging cables.

- The limit switch must also be able to switch off its own extinguishing pump.

- The limit switch must be independent of the level warning device, but may be coupled to the level indicator. When deleting using the on-board pump, it must be able to be disconnected from the shore system.

For this purpose, a separate, on-board, intrinsically safe current loop on the shore must be interrupted by an electrical contact.