PETROL STATION

SECU MULTI TANK consists of the following components:

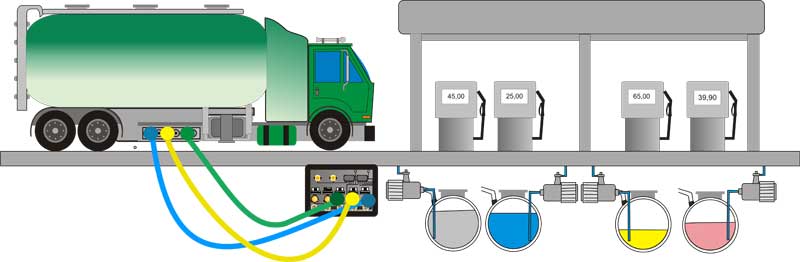

Petroleum companies and hauliers want to prevent product mix and overfilling, which occurs when unloading the tank truck at the petrol stations or when loading at the loading facilities. As a result, oil companies and hauliers are eliminating the tremendous costs and burdens associated with crossfill and overfill accidents to protect their reputation and brand.

The complete system "SECU Multi Tank" contains all components for the fuel delivery, starting with the loading of the tank truck at the gantry until the fuel is unloaded at the filling station. Quality assurance (Cross-Fill-Prevention), overfill prevention, vapour recovery and grounding control are integrated. Faulty refueling and environmental damage caused by overfilling are thereby not possible.

Available components for the petrol station:

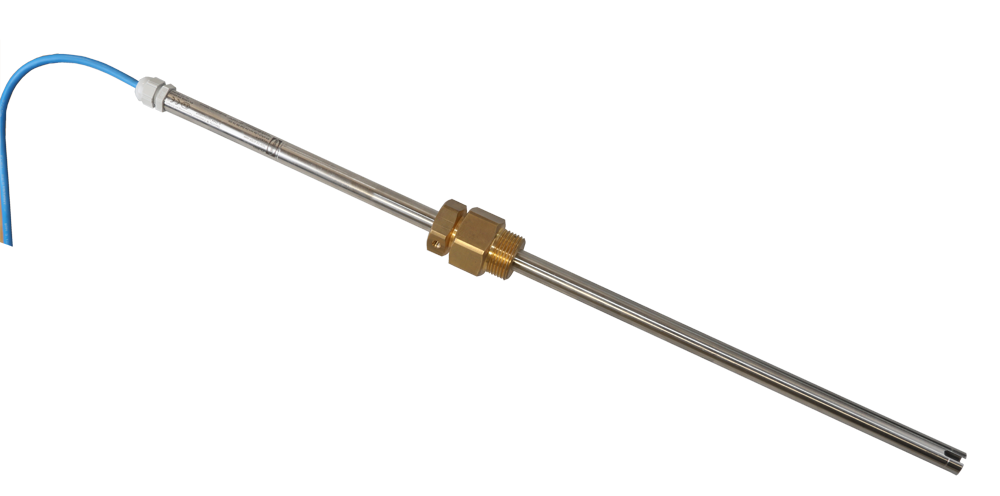

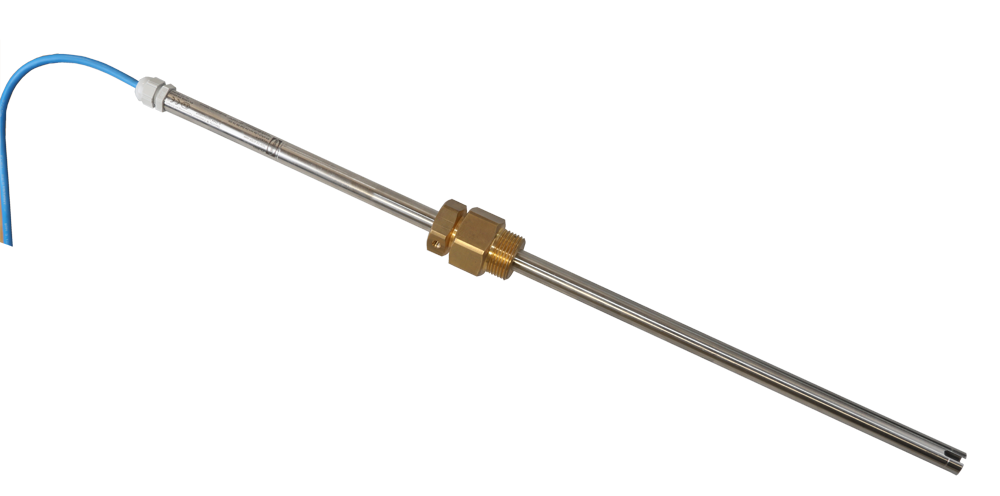

- SECU MultiPID (for central filling points)

- SECU SinglePID (for single compartment couplings)

- SECU O2-PID - the innovative system for product mixing prevention and electronic overfill prevention in a single system

- SECU Multiplexer - for monitoring up to 6 electronic limit switches

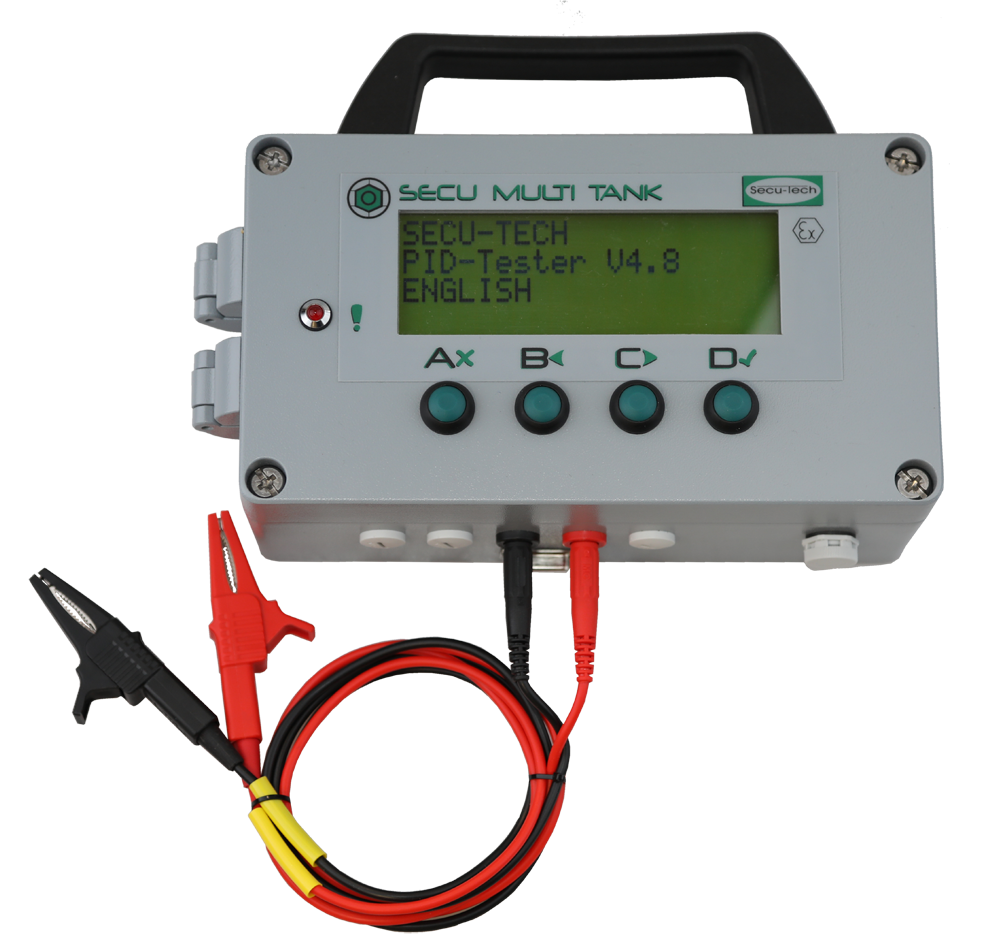

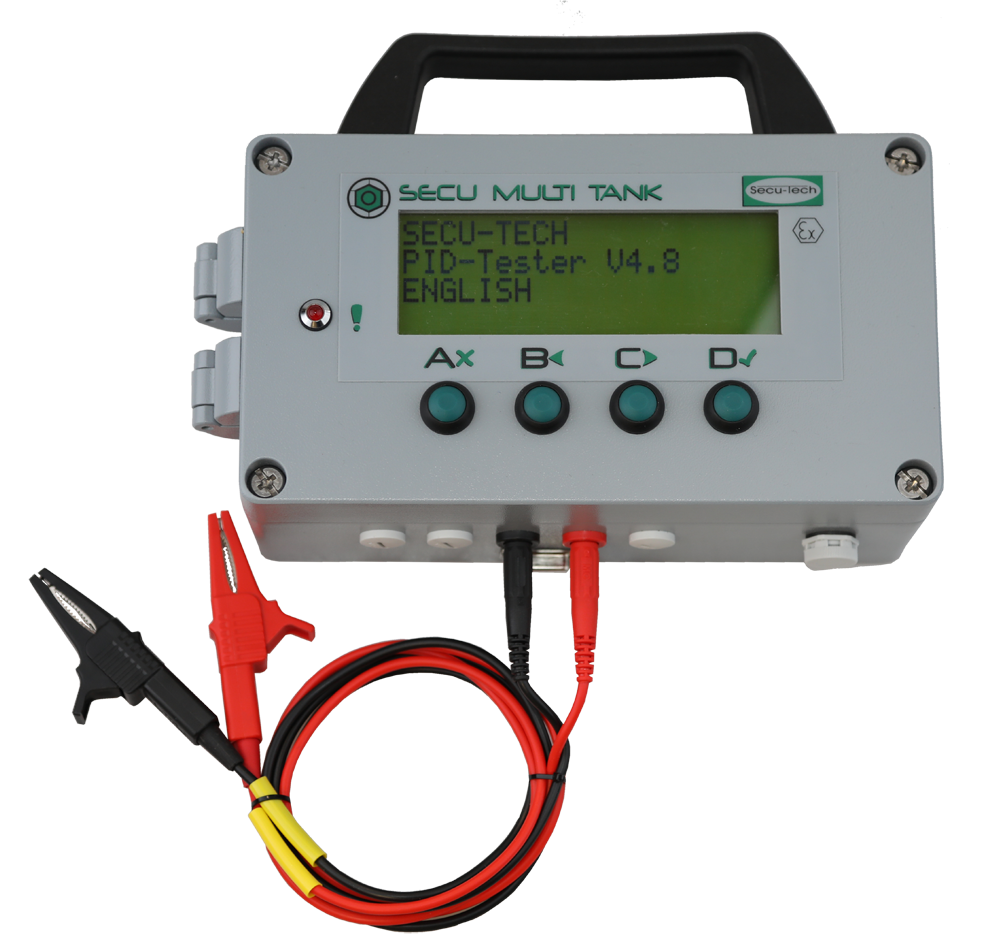

- SECU PID Tester for testing the correct programming and installation, plus reprogramming of SECU SinglePIDs and SECU O2 PIDs, as well as for service and maintenance purposes (installers and contractors)

- SECU USB / 232 ATEX certified adapter for programming and reprogramming the SECU MultiPIDs also inside the EX zone (installers and contractors)

- Insulated couplings of various sizes and types

At the petrol station, a SECU MultiPID or SECU SinglePID is installed (depending on whether it is a central filling or single filling shaft).

The corresponding product code can be programmed directly at the petrol station and during installation with the PC via an EX-approved interface adapter or with the SECU PID Tester. Each coupling is isolated from earth and a ground connection is made via the respective PID.

The installation is very simple and requires no power connection in the filling shaft.

The programming can be stored on the PC and is available for later retrieval

in case of a product change.

The earthing clamp on the tank truck will continue to be used as usual.

Vapour recery connections can also be monitored.

Possibility for later upgrade to an electronic overfill prevention:

- Electronic overfill prevention

SECU MultiPower is already equipped with switching amplifiers for the connection of cable overfill prevention (up to 6 channels are available in 1 MultiPower). Therefore, no additional switching amplifiers are needed on the tank truck.

The tanks at the petrol station must be equipped with electronic limit probes and connections.

Or you better use -

SECU O2 PID - if you choose crossfill prevention and electronic overfill prevention, this is the optimal, innovative solution. O2-PID is a combination of both solutions in 1 system.

When using the O2 PID in your service station tank , both the product crossfill prevention information and the overfill prevention information are routed through the conductive hose to the tank truck controller. There are no further cable connections between tank truck and petrol station needed.

Another option for overfill prevention is provided by the SECU Multiplexer in the filling shaft of the filling station. It can manage up to 6 electronic overfill prevention devices and process it from the tank truck to the filling station with only 1 cable connection. This cable also provides a perfect ground connection.

As an option for electronic overfill prevention, data from existing Level Gauging systems can also be analyzed with the SECU Multiplexer.

SECU MultiPID, SECU Single PID, SECU O2 PID and SECU PID testers do not require power and are ATEX certified.

The system is designed according to EN14116 or EN13616, so that the vehicle electronics from other manufacturers can also evaluate the PID and overfill prevention information accordingly.

The ATEX Approved SECU PID Tester is designed to verify proper installation and programming of the SECU SinglePIDs and SECU O2 PIDs and is perfectly suited for service and maintenance purposes.

The ATEX certified SECU USB / 232 adapter is used to (re) program the SECU MultiPIDs in the EX zone. The data of the petrol station can be stored on the PC and re-read or retrieved and changed.