SECU Multi PID

Channel switching and ModBus

- The first two product channels can be duplicated and allow the depot to deliver two different products in succession via the same loading arm. These can be switched via a switch or via the Modbus from the control panel. Furthermore, all channels can be reprogrammed during operation via the Modbus in order to be able to change products and produce different product compositions.

Cost-Effective:

- It is only a small electronics instead of 6 individual PIDs necessary, the new (re) programming can be done locally.

Highest safety:

- Each individual product and vapor recovery connection is individually monitored

ATEX certified:

- for zone 0: The SECU MultiPID is installed in the filling shaft of the petrol station or at the loading arms at the gantry.

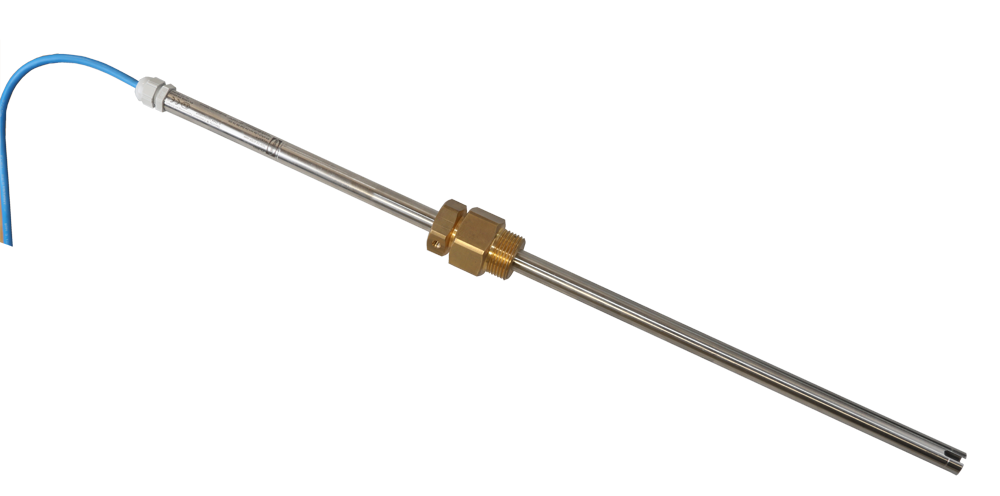

PRODUCT IDENTIFICATION TO AVOID PRODUCT MIXTURES

- Electronic unit: digital information about the product in the tank (e.g. gasoline, diesel, etc.)

- Replacement for single PIDs (tags)

- Reconfiguration (reprogramming) possible on site during product change.

- Data format complies with the latest standards (EN 14116, EN 13616)

- No power supply required

- ATEX certified for Zone 0

BENEFITS OF SECU Multi PID:

- Replacement for single PIDs (tags): Only one unit is required for up to 6 product and vapor recovery connections, the system can be extended to any number of tank compartments.

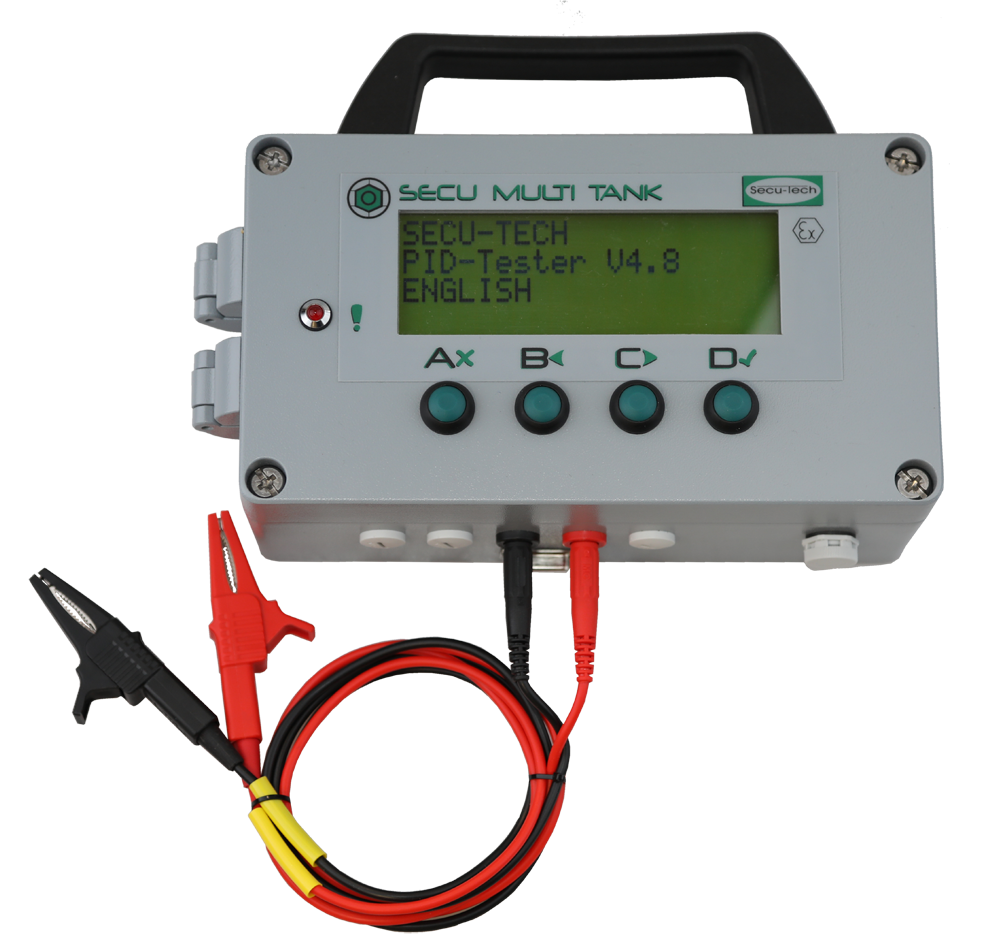

- Reconfiguration possible at product change on site. The programming with an easy-to-use software via a special intrinsically safe USB adapter (this is ATEX certified) or the standardized ModBus.

- Data format complies with the latest standards (EN 14116, EN 13616) The SECU MultiPID is fully compatible with all common tanker-truck management and cross-fill-prevention systems on the market.

- No power supply required. The SECU MultiPID is supplied from the tank truck vehicle via the conductive product and vapor recovery hoses.